PCB Panelize Methods and Attentions

Why we need to panelize

After the finished the PCB design of the entire board, the PCB needs to be mounted on the SMT patch assembly line to paste the components. Each SMT processing factory will specify the most suitable size of the PCB according to the processing requirements of the assembly line, such as the size is too small or too large, The tooling for fixing the PCB on the assembly line cannot be fixed. So the question is, what if the size of our PCB itself is smaller than the size specified by the factory? That is, we need to put the circuit boards together and put multiple PCB into one piece. Imposition can significantly improve efficiency for both high-speed placement machines and wave soldering. You can easily separate multiple boards when doing imposition to avoid damage to the PCB during separation. Determine which type of imposition method to use according to the shape of a single type of imposition.

There are three main methods to panelize PCB boards:

V-CUT, punching slots, and stamp hole. The size of the panel can not be too large or too small. Generally, small boards can be assembled or solder for convenience.

1. V-CUT

V-CUT means that several boards or the same boards can be combined and spliced together, and then after the PCB processing is completed, a V-shaped groove is cut between the boards with a V-CUT machine, which can be broken during use. It is the more popular way now.

2. Punching Slot

Punching refers to milling out between the board or the inside of the board with a milling machine as needed, which is equivalent to digging out.

3. Stamp Hole

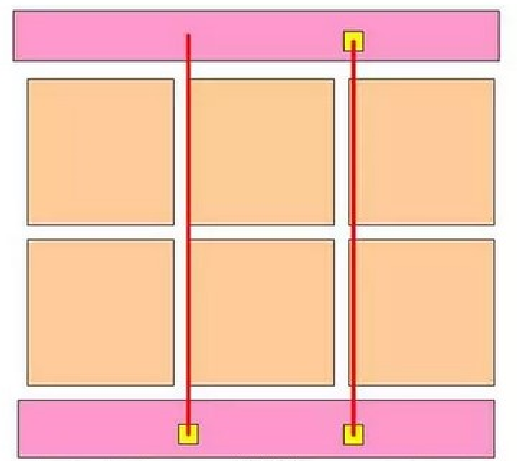

The so-called stamp use is to link the board to the board with a small hole, which looks like the zigzag on the stamp, so it is called the stamp hole link. The stamp hole link requires high-control burrs on all sides between the board and the board, that is, only one stamp hole can be used instead of the V line.

Ten points of attentions for PCB panelization:

1. The outer frame (clamping side) of the PCB jigsaw should adopt a closed loop design to ensure that the PCB jigsaw will not be deformed after being fixed on the fixture.

2. PCB board width ≤260mm (SIEMENS line) or ≤300mm (FUJI line); if automatic dispensing is required, PCB board width×length ≤125mm×180mm.

3. The PCB board shape should be as close as possible to the square. It is recommended to use 2×2, 3×3...

4. The center distance between the small plates is controlled between 75mm~145mm.

5. When setting the reference positioning point, usually leave a non-resistance area 1.5mm larger than it around the positioning point.

6. There should be no large devices or protruding devices near the connection point between the outer frame of the jigsaw and the inner small board, and the small board and the small board, and there should be more than 0.5mm space between the components and the edge of the PCB board. To ensure the normal operation of the cutting tool.

7. Four positioning holes are made at the four corners of the frame of the jigsaw, with a diameter of 4mm±0.01mm; the strength of the holes should be moderate to ensure that they will not break during the upper and lower boards; the precision of the hole diameter and position should be high, and the hole wall should be smooth and free of burrs.

8. Each small board in the PCB puzzle board must have at least three positioning holes, 3≤aperture≤6mm, and no wiring or patching is allowed within 1mm of the edge positioning hole.

9. The reference symbols used for the positioning of the entire PCB and the positioning of fine-pitch devices. In principle, the QFP with a spacing of less than 0.65mm should be WHERE set in its diagonal position; the positioning reference symbols used for the imposition PCB daughter board should be paired Used, arranged at the opposite corner of the positioning element.

Capacités

Capacité PCB rigide

Capacité PCB flexible

Capacité d'assemblage PCB

Équipement PCB

Équipement d'assemblage PCB

Méthodes de paiement

Prix spéciaux

Transporteurs

Support pour amateurs

Certificat

Assistance clientèle

Suivez-nous

Tel: 1-905-339-2881

Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2026

Tel: 1-905-339-2881 Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Système de contrôle qualité | Service produit

| Liens

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2026