USING STIFFENERS ON FLEXIBLE PCBS

A stiffener is defined as a piece of material adhered to a flexible printed circuit board that rigidizes one zone of the board. While a stiffener holds no electrical value to a PCB, it does maintain a crucial part of most flexible PCBs in the market by hardening that portion of the board.

This rigidized section occurs for numerous reasons, ranging from meeting thickness requirements for assembly to creating a stable and flat area of the board, and from allowing for better handling of the PCB to support plated portions of the PCB, and support component areas.

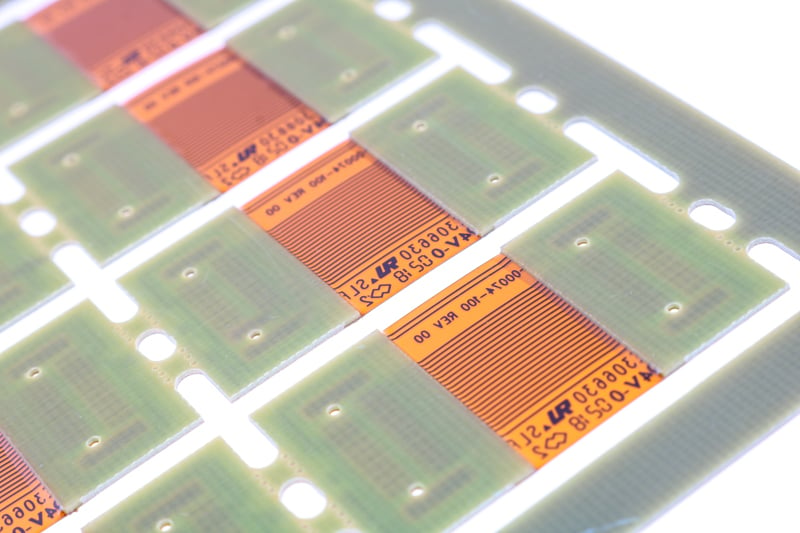

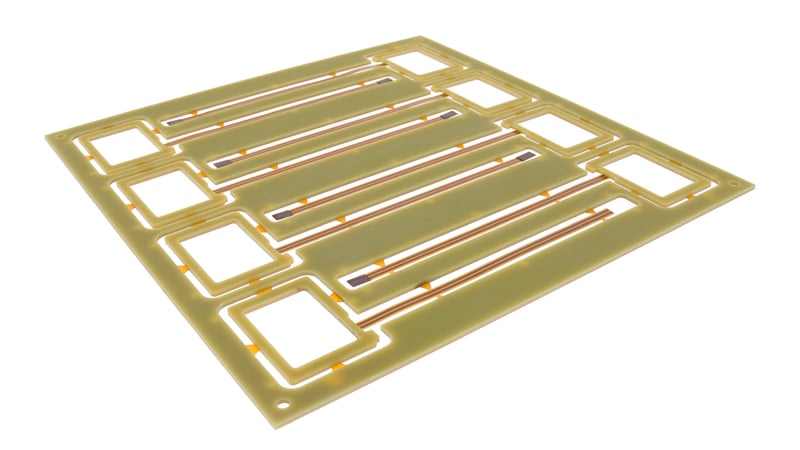

Example of a flexible circuit board with stiffeners.

Thickness Requirements

A common feature that flexible circuits share with rigid circuit boards is that typically there is a necessary thickness to meet assembly requirements. Typically, this is to accomplish mounting within a certain area, ensuring a consistent thickness that could be needed to maintain repeatability and common parts, like mounting screw lengths for a board. However, with flexible circuits, to maintain flexibility they tend to be extremely thin comparatively, making activities such as mounting to housing difficult. To circumvent this, a stiffener can be added that grants a thicker portion of the circuit without sacrificing flexibility.

Another common reason to need a stiffener is to meet thickness requirements that involve zero insertion force (ZIF) connectors. These connectors require a strict thickness to ensure the component properly clamps onto the board. Whenever a ZIF connector is used, a polyimide stiffener will make up the difference between what the board cannot achieve in thickness to meet that ZIF thickness requirement.

A Stable and Flat Area

While the flexibility of a circuit board can be an advantage, it can also create a large disadvantage. If a flexible circuit were to be installed and suspended, for instance, any components would greatly sag areas. With a stiffener, this sagging is drastically reduced, allowing the board to be freely suspended. This is an incredibly niche case, but for a more specific case, it can allow for a flexible circuit to keep surface mount components and other items from contacting one another if the board were to bend. By placing the stiffener on the board, this area is forced to remain flat, thus creating stability and drastically reducing that point of failure.

Better Handling

This point is almost entirely straightforward. It can be difficult to handle a flexible circuit. From manufacture, to assembly, to installation, and everyday use, a flexible circuit has many chances to rip or tear.

Flex PCB with stiffeners applied for support and ease of handling during assembly.

By adding a stiffener, the board can be easier to handle and prevent mishandling accidents that could damage or destroy the board. The thinner the board, the easier it is to damage, making stiffeners much more important at lower thicknesses.

Supporting Plated Areas

Typically, most flexible circuits only have plating in a method called ‘pad plating’, where only the through hole and via holes are plated alongside the pads on either side. While this is an effective method of plating for flexible circuits, it can create opportunities for intermittent opens if these holes are in a region that experiences bending. This is due to plated copper being unsuitable for bending, where the grain direction of the copper can make it more brittle than typical rolled annealed copper for flexible areas.

As a result, stiffeners are used in those areas to support the plated holes, preventing that region from bending, which prevents the hole plating from fracturing during bending which could create intermittent opens or even full opens.

Supporting Component Areas

Per IPC-2223, the recommendation for flexible circuits is to install stiffeners in locations and regions where components are placed to support them. The reason for this is twofold. The first reason is due to the previous section, that in areas where components are placed, sometimes there are plated holes as well, warranting a need for a stiffener. The second reason is that components are adhered to using solder joints. While these solder joints are effective at holding down components, if they were to bend, they could rip away copper from the board, break the copper, or break the joint, thus leaving the board damaged and unusable.

Summary

One of the most crucial parts of a flexible circuit board is the stiffener. Without a stiffener, many functions and applications of the circuit would be heavily limited or even impossible. Without stiffeners, components would be harder to install, the boards flexible circuit areas would be harder to handle, plated holes would run the risk of breaking, ZIF connectors and components would be harder to install, or would not exist, and in some applications the board would be unstable. But because of stiffeners, all of these are possible and more.

Please login and click here to download the PDF file: